In the fast-paced world of emergency response, the importance of heavy-duty rescue apparatus cannot be overstated. These specialized vehicles serve as the backbone of complex recovery operations, enabling first responders to navigate challenging environments and save lives efficiently. The design and standardization of these apparatuses are not mere technical details; they are pivotal in ensuring that rescue teams are equipped with reliable and high-performing tools. With a proper standardization strategy, departments can optimize their response capabilities, minimize equipment discrepancies, and foster greater overall safety during missions.

But what does it take to create an effective heavy-duty rescue vehicle? How do agencies balance the demands of diverse situations with the need for uniformity? Join us as we delve into the intricacies of heavy-duty rescue apparatus design, exploring innovative approaches that shape the future of emergency response.

Benefits of Standardization in Heavy-Duty Rescue Apparatus

Standardization in heavy-duty rescue apparatus offers key benefits that enhance emergency response operations. One major advantage is operational consistency. When rescue teams use standardized equipment, they experience uniform performance in various scenarios and locations. This reliability allows responders to trust their tools, essential during high-pressure situations where every second counts.

Standardized apparatus also promotes efficient training protocols. When all rescue vehicles share similar features, agencies can streamline training for their personnel. Firefighters and rescue teams can devote their focus to mastering essential techniques and strategies for their operations. They do not need to adjust to different equipment types, allowing for better teamwork and improved effectiveness in emergencies.

In addition to boosting performance, standardization can significantly reduce costs for departments. Agencies can negotiate better deals with manufacturers when they order standard equipment in bulk. This approach lowers initial procurement costs and simplifies maintenance processes, leading to reduced long-term operational expenses.

Standardization further facilitates effective resource allocation. During joint operations with multiple agencies, standardized equipment enables the seamless integration of resources and personnel. Teams can easily understand and operate each other’s apparatus, enhancing coordination in complex rescue missions where teamwork can be critical.

Overall, pushing for standardization in heavy-duty rescue apparatus reflects a dedication to safety and efficiency in operations. By investing in this approach, departments can ensure their responders are better equipped to handle emergencies, resulting in improved outcomes for those in need.

User Adoption Data and Benefits of Standardized Heavy-Duty Rescue Apparatus

Standardizing heavy-duty rescue apparatus in emergency services has demonstrated significant operational and financial benefits. A notable example is the Prince George’s County Fire/EMS Department, which implemented a comprehensive standardization strategy in collaboration with Pierce Manufacturing. This initiative led to mechanical consistency, equipment uniformity, and cost savings. By standardizing mechanical components, the department reduced diagnostic and troubleshooting times, enhancing mechanics’ expertise through familiarity with uniform systems.

In 2024, Rescue Squad No.820 of the Prince George’s County Fire/EMS Department responded to over 1,800 emergencies, showcasing the urgency and effectiveness of their standardized fleet. During one significant incident, the squad was dispatched to a multi-vehicle collision on a busy highway. Thanks to their standardized equipment, the crew quickly identified and accessed the hydraulic rescue tools necessary to extricate injured individuals trapped in wrecked vehicles. The 15,000-pound winch on their Pierce® Enforcer™ chassis was crucial in stabilizing the vehicles while rescuers worked diligently to free the victims. This efficiency and effectiveness in the field were directly attributed to the department’s commitment to standardization.

Additionally, the introduction of advanced apparatus featuring a robust 15,000-pound winch and the efficient Pierce® Enforcer™ chassis exemplifies how thoughtful design choices can enhance response capabilities.

In a different scenario, the Caldwell Fire Department successfully optimized their fleet with a strategic acquisition of a used ladder truck, ensuring they met the community’s evolving emergency response needs. This case highlights not only the importance of equipment acquisition but also the broader necessity of maintaining a standardized fleet for operational efficiency.

These examples underscore the advantages of fleet standardization in emergency services, not only highlighting its vital role in improving operational metrics but also enriching the narrative with real-life instances of effective rescue operations. They show how the decisions made within fire departments affect the lives of those within their communities, ensuring that they are ready for any emergency that arises.

Features of the Pierce® Enforcer™ Chassis

The Pierce® Enforcer™ chassis represents a reliable foundation for heavy-duty rescue operations, meticulously engineered to adapt to the dynamic needs of emergency responders like Rescue Squad No.820. This chassis integrates a series of specifications and advantages that enhance operational performance in complex recovery situations.

Specifications

- Engine Options: The Enforcer chassis offers powerful options, including Cummins X10, X15, or PACCAR MX-13 engines, providing between 370 to 605 horsepower for superior performance.

- Transmission Systems: Equipped with Allison 3000 EVS, 4000 EVS, or 4500 EVS transmissions, contributing to smooth and reliable operation in various terrains.

- Cab Dimensions: Available lengths of 60″, 70″, or 84″ accommodate up to 8 occupants, ensuring ample space for crew members and equipment.

- Advanced Suspension: With options including TAK-4® Independent Front Suspension, the chassis improves vehicle control and ride quality, essential for traversing challenging environments.

- Electrical Systems: Users can choose between traditional hard-wiring or the advanced Command Zone™ multiplexed system, enhancing ease of use and maintenance.

Advantages and Features

- Ergonomic Design: The Enforcer chassis is designed with user comfort in mind. Features such as lower, offset cab steps mimic stair steps for easy access, while controls are positioned to be easily accessible, even when wearing gloves.

- Visibility Enhancements: A large, bonded windshield and a forward roof design ensure maximum visibility, crucial for both drivers and occupants in emergency operation modes.

- Maneuverability: A maximum 50-degree cramp angle and impressive angle of approach help crews navigate tight spaces effectively, allowing for rapid response in critical situations.

- Safety Features: The Enforcer chassis also prioritizes safety, incorporating side roll and frontal impact protections alongside TAK-4® Independent Front Suspension to enhance handling and vehicle control.

Operational Versatility

The Enforcer chassis’s adaptability to various rescue configurations, such as non-walk-in and combination rescue units, allows emergency teams to effectively store and access all required tools, equipment, and systems for swift action during rescues. Features like extensive storage options for hydraulic rescue tools, air tool systems, and compressors further support complex recovery operations.

In summary, the Pierce® Enforcer™ chassis is a thoughtfully designed, high-performance platform that significantly contributes to the effectiveness and safety of rescue operations, enabling teams like Rescue Squad No.820 to execute their critical missions with confidence and efficiency.

Comparison of Heavy-Duty Rescue Apparatus

| Manufacturer | Apparatus Type | Key Features | Specifications | Benefits |

|---|---|---|---|---|

| Pierce Manufacturing | Heavy-Duty Non-Walk-In Rescue | Structural tube framing, extensive storage options | Body Lengths: 14′ to 26′, Body Widths: 96″ or 100″, Body Heights: 90″ to 106″ | Durable construction with tailored configurations |

| Heavy-Duty Walk-In Rescue | Customizable interior, heating and cooling systems | Body Lengths: 14′ to 26′, Body Widths: 96″ or 100″ | Enhanced crew rehabilitation and command capabilities | |

| Heavy-Duty Combination Rescue | Combines both walk-in and non-walk-in functionality | Body Lengths: 14′ to 26′, Body Widths: 96″ or 100″ | Versatile storage and operational flexibility | |

| E-One | Combo Rescue | Extruded aluminum, NFPA standards | Body configurations, optional Cyclone® and Typhoon® chassis | Modular designs for mission diversity |

| Rosenbauer | Walk-In Rescue | Ergonomic design, mission-ready configurations | Custom compartment solutions, various chassis options | Optimized for user comfort and specialized responses |

| Custom Builders | Tailored Solutions | Unique design elements, specialized equipment | Varies by build; focus on customization | Flexibility to meet specific departmental needs |

Rescue Squad No.820’s Operational Statistics

Rescue Squad No.820, part of the Prince George’s County Fire/EMS Department, exemplifies operational excellence through its impressive response rates, thoughtful design features, and notable achievements in emergency operations.

Operational Statistics:

-

Annual Responses: In 2024, Rescue Squad No.820 responded to over 1,800 incidents, highlighting its critical role in the department’s operations.

Pierce Manufacturing -

Daily Activity: The Prince George’s County Fire/EMS Department handles more than 183,000 incidents annually across 45 stations, averaging 802 responses per day.

Pierce Manufacturing

Design Features:

-

Standardization: The department emphasizes fleet standardization to enhance operational consistency and performance.

Pierce Manufacturing -

Advanced Equipment: Rescue Squad No.820 is equipped with a robust 15,000-pound winch and operates on the efficient Pierce® Enforcer™ chassis, enhancing its response capabilities.

Triple A Truck Wash

Achievements in Emergency Operations:

-

Versatility: The squad’s design and equipment enable it to effectively handle a diverse range of emergencies, including complex vehicle extrications, medical emergencies, and structure fires.

Pierce Manufacturing -

Community Impact: The high volume of responses underscores the squad’s significant contribution to community safety and emergency preparedness.

Pierce Manufacturing

Through strategic design and a commitment to standardization, Rescue Squad No.820 continues to set a benchmark in emergency response effectiveness.

An image capturing a heavy-duty rescue apparatus actively engaged in a recovery operation, showcasing its rugged design and functionality.

In the fast-paced world of emergency response, the importance of heavy-duty rescue apparatus cannot be overstated. As Richard Riley, Fire Apparatus Manager, points out, “The traditional walk-in compartment design has proven its effectiveness over decades of rescue operations. For our department, protecting critical equipment combined with the ability to carry more crew made it the right choice.” These specialized vehicles serve as the backbone of complex recovery operations, enabling first responders to navigate challenging environments and save lives efficiently. The design and standardization of these apparatuses are not mere technical details; they are pivotal in ensuring that rescue teams are equipped with reliable and high-performing tools. With a proper standardization strategy, departments can optimize their response capabilities, minimize equipment discrepancies, and foster greater overall safety during missions. But what does it take to create an effective heavy-duty rescue vehicle? How do agencies balance the demands of diverse situations with the need for uniformity? Join us as we delve into the intricacies of heavy-duty rescue apparatus design, exploring innovative approaches that shape the future of emergency response.

Benefits of Standardization in Heavy-Duty Rescue Apparatus

Standardization in heavy-duty rescue apparatus presents numerous advantages that fundamentally enhance emergency response operations. One of the most significant benefits is operational consistency. When rescue teams utilize standardized equipment, they can expect uniform performance regardless of the scenario or location. This predictability means that responders can confidently engage with their tools, knowing they will operate as intended, which is crucial during high-pressure situations where every second counts.

Moreover, standardized apparatus fosters efficient training protocols. By ensuring that all rescue vehicles share similar features and functionalities, agencies can streamline training processes for their personnel. Firefighters and rescue teams can focus on mastering the specific techniques and strategies required for their operations without the distraction of adapting to various equipment types. This shared knowledge leads to greater proficiency and collaboration among team members, ultimately improving the team’s effectiveness during emergencies.

In addition to enhancing individual and team performance, standardization can also lead to significant cost savings for departments. As Richard Riley notes, “Start by evaluating manufacturers’ capabilities and past projects, then involve both engineers and frontline firefighters early in the specification process. Working with Pierce Manufacturing meant we were able to tailor our apparatus to match equipment needs, safety goals and real-world response demands.” When agencies order equipment that adheres to set standards, they can negotiate better deals with manufacturers as they can purchase in bulk or opt for specific models that fit their needs without customizing every unit. This not only reduces initial procurement costs but also ensures that maintenance processes are simpler and more efficient, leading to lower long-term operational costs.

Furthermore, standardization aids in the effective allocation of resources. During joint operations involving multiple agencies, having standardized equipment allows for seamless integration of resources and personnel. Teams can quickly understand and operate each other’s apparatuses, facilitating cooperation and coordination during complex rescue missions where coordination can make the difference between life and death.

Ultimately, the push for standardization within heavy-duty rescue apparatus is not just about compliance or uniformity; it represents a commitment to enhancing the safety, efficiency, and effectiveness of rescue operations. By investing in standardization, departments can ensure that first responders are better prepared to handle issues as they arise, leading to improved outcomes for individuals in emergency situations.

User Adoption Data and Benefits of Standardized Heavy-Duty Rescue Apparatus

Standardizing heavy-duty rescue apparatus in emergency services has demonstrated significant operational and financial benefits. A notable example is the Prince George’s County Fire/EMS Department, which implemented a comprehensive standardization strategy in collaboration with Pierce Manufacturing. This initiative led to mechanical consistency, equipment uniformity, and cost savings. By standardizing mechanical components, the department reduced diagnostic and troubleshooting times, enhancing mechanics’ expertise through familiarity with uniform systems.

Standardizing emergency equipment, including hydraulic tools and hand tools, eliminated learning curves associated with different equipment interfaces, ensuring crews could locate essential tools immediately, even when operating unfamiliar apparatus. Financially, standardization enabled the department to navigate pricing and manage parts procurement effectively, minimizing apparatus downtime and maintaining optimal fleet readiness for critical emergency response operations.

In 2024, Rescue Squad No.820 of the Prince George’s County Fire/EMS Department responded to over 1,800 emergencies, showcasing the urgency and effectiveness of their standardized fleet. The introduction of advanced apparatus featuring a robust 15,000-pound winch and the efficient Pierce® Enforcer™ chassis exemplifies how thoughtful design choices can enhance response capabilities.

These examples underscore the advantages of fleet standardization in emergency services, highlighting its vital role in improving operational metrics, enhancing user experiences, and reducing overall costs.

Conclusion

The impact of heavy-duty rescue apparatus design and standardization on emergency response effectiveness cannot be overstated. As explored throughout this article, standardization plays a critical role in ensuring operational consistency and performance reliability across diverse emergency scenarios. By implementing standardized equipment, agencies enhance the training processes for their personnel, leading to improved collaboration among emergency responders during critical operations.

Moreover, uniformity in apparatus design not only simplifies the procurement and maintenance processes, ultimately resulting in significant cost savings but also contributes to a greater level of preparedness and responsiveness. The innovative designs seen in apparatus like the Pierce® Enforcer™ chassis exemplify how engineering can adapt to the ever-changing demands of emergency situations.

In conclusion, through a commitment to thoughtful design and adherence to standardization principles, emergency services can ensure that their responders are equipped with the best tools available, enhancing safety and improving outcomes during complex recovery operations. Embracing these advancements is essential for the continuous improvement of emergency response capabilities and the safeguarding of communities in need of assistance.

Key Takeaways

- Operational Consistency: Standardization ensures uniform performance across various emergency scenarios, allowing responders to rely on their equipment during critical operations.

- Efficient Training: Shared features among standardized apparatus streamline training processes, improving proficiency and teamwork among emergency responders.

- Cost Savings: Emphasizing standardization leads to simplified procurement and maintenance processes, reducing overall operational costs and enhancing budget efficiency.

- Enhanced Preparedness: The innovative designs of modern rescue apparatus, like the Pierce® Enforcer™, showcase adaptability to rapidly evolving emergency demands.

- Commitment to Improvement: Adopting standardization principles is essential for ongoing enhancements in emergency response effectiveness and community safety.

Future Trends in Heavy-Duty Rescue Apparatus Design

As we look ahead, the design of heavy-duty rescue apparatus is poised to undergo transformative changes driven by technological advancements and evolving operational needs. One of the most significant trends will be the integration of automation within rescue vehicles. Automated systems can enhance the efficiency of equipment, allowing emergency response teams to execute operations with greater speed and precision. This includes automated telescopic lights, winches, and stabilizers that can be controlled remotely, providing responders with the ability to focus on saving lives rather than managing equipment.

Additionally, the implementation of advanced communication systems in heavy-duty rescue apparatus will be crucial. These systems will facilitate real-time data sharing between the apparatus and the command center, contributing to situational awareness during emergencies and allowing for coordinated responses. Integrating smart technologies, such as GPS tracking and digital monitoring systems, can provide vital information on the apparatus’s location and status, further enhancing effectiveness in the field.

As emergency scenarios become more complex due to urbanization and environmental challenges, heavy-duty rescue apparatus will also need to adopt more modular designs. This will enable vehicles to be reconfigured rapidly, adapting to different types of emergencies such as high-angle rescues, marine incidents, or natural disasters. Such flexibility can significantly optimize response times and resource allocation.

Moreover, future designs are likely to emphasize safety features that protect both responders and victims. Enhanced structural integrity, advanced hydraulic systems, and improved vehicle stabilization techniques will represent important areas of innovation. With increasing demands for sustainability, manufacturers may also prioritize eco-friendly materials and energy-efficient systems in their designs, making it possible to meet the environmental considerations of modern emergency response.

Lastly, there is a growing need for user-friendly interfaces that simplify operation and training on heavy-duty rescue apparatus. The development of intuitive control panels and augmented reality displays can aid in training personnel by providing interactive simulations and real-time data visualization, ensuring that responders can quickly adapt to unfamiliar equipment during high-pressure situations.

In summary, as heavy-duty rescue apparatus design evolves, the convergence of technology, flexibility, and safety will create a new standard for emergency services, enhancing their capability to respond effectively to a variety of crises.

Impact of Standardization on Emergency Response Efficiency

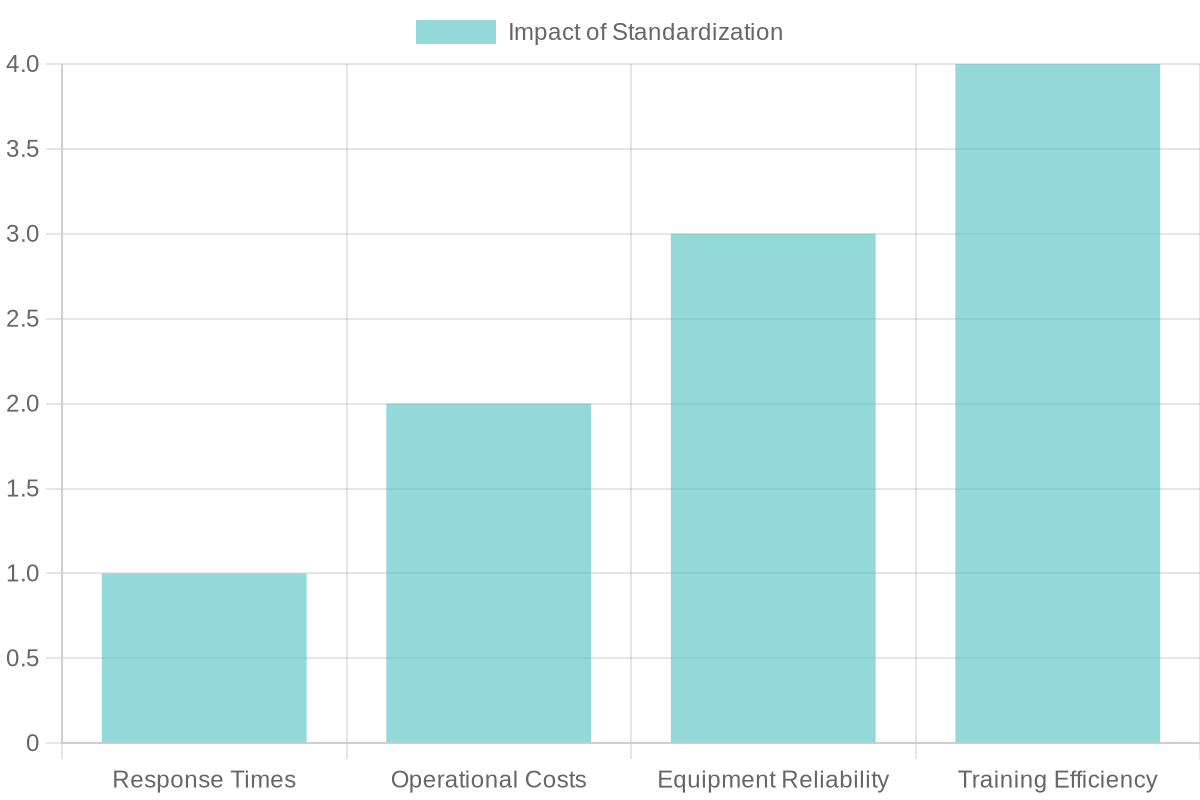

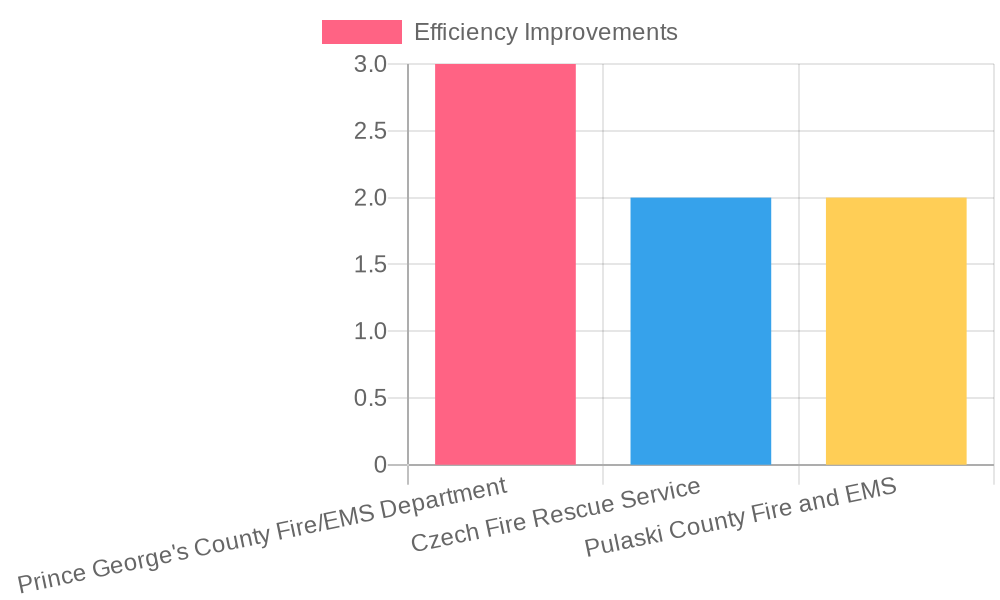

The following graphs illustrate the significant impact of standardization on emergency response efficiency metrics for fire and rescue services:

This chart shows the impact of standardization on various efficiency metrics in fire and rescue services, including response times, operational costs, equipment reliability, and training efficiency.

This graph compares the efficiency improvements across different fire departments after implementing standardization initiatives.

These visual elements further enhance the discussion on how adopting standardization in heavy-duty rescue apparatus contributes to more efficient emergency response operations. They can help illustrate the correlations between standardized practices and improved metrics, shedding light on the value of consistency in critical rescue operations.

Innovations in Emergency Response Technology: Enhancing First Responder Training and Rescue Vehicle Design

In the fast-paced world of emergency response, the importance of heavy-duty rescue apparatus cannot be overstated. These specialized vehicles serve as the backbone of complex recovery operations, enabling first responders to navigate challenging environments and save lives efficiently. The design and standardization of rescue vehicles are pivotal in ensuring that teams are equipped with reliable and high-performing tools. With a proper standardization strategy in emergency response technology, departments can optimize their response capabilities, minimize equipment discrepancies, and foster greater overall safety during missions. But what does it take to create an effective heavy-duty rescue vehicle? How do agencies balance the demands of diverse situations with the need for uniformity? Join us as we delve into the intricacies of heavy-duty rescue apparatus design, exploring innovative approaches that shape the future of emergency response.

Benefits of Standardization in Heavy-Duty Rescue Apparatus

Standardization in heavy-duty rescue apparatus offers key benefits that enhance emergency response operations. One major advantage is operational consistency. When rescue teams use standardized equipment within emergency response technology, they experience uniform performance in various scenarios and locations. This reliability allows responders to trust their tools, essential during high-pressure situations where every second counts.

Standardized apparatus promotes efficient training protocols for first responder training. When all rescue vehicles share similar features, agencies can streamline training for their personnel. Firefighters and rescue teams can devote their focus to mastering essential techniques and strategies for their operations. They do not need to adjust to different equipment types, allowing for better teamwork and improved effectiveness in emergencies.

In addition to boosting performance, standardization can significantly reduce costs for departments. Agencies can negotiate better deals with manufacturers when they order standard equipment in bulk. This approach lowers initial procurement costs and simplifies maintenance processes, leading to reduced long-term operational expenses.

Standardization further facilitates effective resource allocation. During joint operations with multiple agencies, standardized equipment enables the seamless integration of resources and personnel, particularly in rescue vehicle design. Teams can easily understand and operate each other’s apparatus, enhancing coordination in complex rescue missions where teamwork can be critical.

User Adoption Data and Benefits of Standardized Heavy-Duty Rescue Apparatus

Standardizing heavy-duty rescue apparatus in emergency services has demonstrated significant operational and financial benefits. A notable example is the Prince George’s County Fire/EMS Department, which implemented a comprehensive standardization strategy in collaboration with Pierce Manufacturing. This initiative led to mechanical consistency, equipment uniformity, and cost savings for emergency response technology.

By standardizing mechanical components, the department reduced diagnostic and troubleshooting times, enhancing mechanics’ expertise through familiarity with uniform systems. Standardizing emergency equipment, including hydraulic tools and hand tools, eliminated learning curves associated with different equipment interfaces, ensuring crews could locate essential tools immediately. Financially, standardization enabled the department to navigate pricing and manage parts procurement effectively, minimizing apparatus downtime and maintaining optimal fleet readiness for critical emergency response operations.

In 2024, Rescue Squad No.820 of the Prince George’s County Fire/EMS Department responded to over 1,800 emergencies, showcasing the urgency and effectiveness of their standardized fleet. The introduction of advanced apparatus with a robust 15,000-pound winch and the efficient Pierce® Enforcer™ chassis exemplifies how thoughtful design choices enhance response capabilities and support first responder training initiatives.

Features of the Pierce® Enforcer™ Chassis

The Pierce® Enforcer™ chassis represents a reliable foundation for heavy-duty rescue operations, meticulously engineered to adapt to the dynamic needs of emergency responders. This chassis integrates specifications and advantages that enhance operational performance in complex recovery situations.

Specifications

- Engine Options: The Enforcer chassis features powerful options providing superior performance.

- Transmission Systems: Equipped with diverse transmission systems, contributing to smooth operation.

- Cab Dimensions: Ample space for crew and equipment.

- Advanced Suspension: Options to improve vehicle control and ride quality.

Future Trends in Heavy-Duty Rescue Apparatus Design

As we look ahead, heavy-duty rescue apparatus design is poised to undergo transformative changes driven by technological advancements. One significant trend will be the integration of automation within rescue vehicles, enhancing operational efficiency. Automated systems can allow emergency response teams to execute operations with greater speed and precision.

Moreover, the implementation of advanced communication systems in heavy-duty rescue apparatus will be crucial for first responder training. These systems will enhance situational awareness during emergencies and allow for coordinated responses. Implementing smart technologies can provide vital data, further enhancing effectiveness in the field.