Towing trucks play a crucial role in modern automotive care and rescue services, making them indispensable for local drivers, car owners, auto repair shops, dealerships, property managers, and HOA administrators. These specialized vehicles are designed to transport and recover disabled, damaged, or improperly parked vehicles while ensuring safety and efficiency. Understanding the different types of towing trucks, including light-duty and heavy-duty models, is essential; each serves unique purposes and meets specific demands in diverse environments. In the following chapters, we will dive into the features and uses of light-duty towing trucks, followed by an overview of the capabilities and specifications of heavy-duty variants. Finally, we will explore the current trends in the towing truck market and highlight suppliers who offer reliable options for your needs.

Tow Light, Move Fast: The Essential Role of Light-Duty Tow Trucks in Urban Recovery

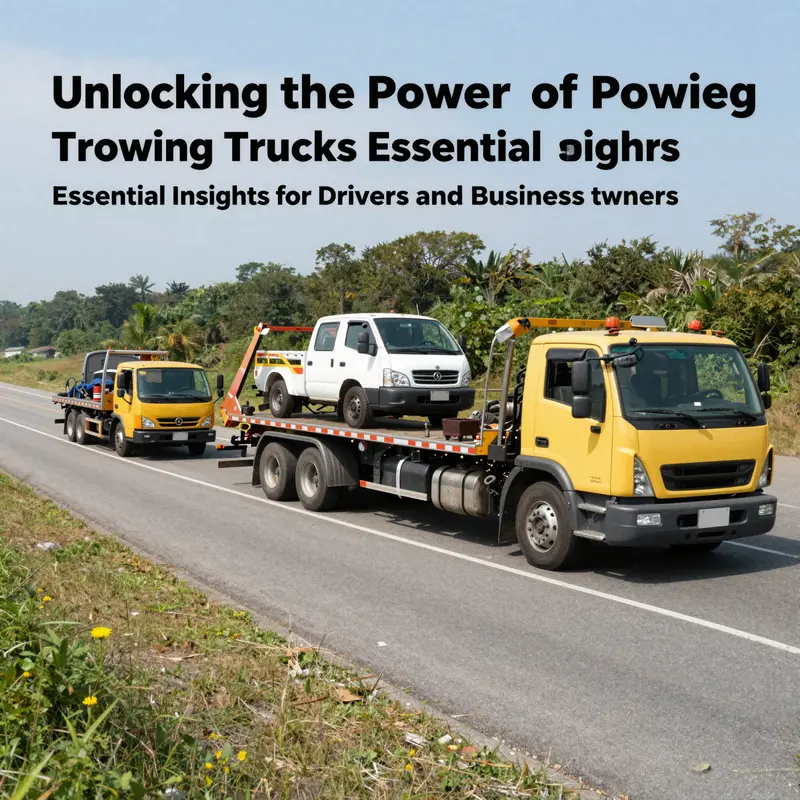

In the rhythm of city streets and suburban corridors, light-duty tow trucks perform a quiet, indispensable service. They arrive quickly, maneuver through tight spaces, and ready a vehicle for transport with a combination of simple engineering and precise human skill. These trucks are not the only recovery machines on the road, but they are often the first to respond when a car stalls, a fender bender blocks a lane, or a vehicle breaks down in a crowded parking lot. Their design philosophy centers on nimbleness, efficiency, and safety, allowing them to operate in environments where larger recovery rigs would struggle or fail to maneuver at all. This emphasis on flexibility reflects a broader trend in road-rescue operations: the value of a capable, lightweight tool that can be deployed rapidly to secure the scene, recover the vehicle, and reduce disruption to the rest of traffic.

At the core of light-duty towing is a rollback or slide-bed concept. The hydraulically operated platform tilts, slides, and lowers to ground level, enabling the operator to load a damaged or disabled vehicle without lifting it onto a high bed. This mechanism minimizes the risk of further damage to the towed vehicle and reduces the physical demands placed on the operator. Loading becomes a two-step, visually straightforward process: position, secure, and roll the vehicle onto the bed. The result is a safer, faster recovery, particularly in start-and-stop traffic conditions or on uneven surfaces where traditional hoisting could be hazardous. In practice, the rollback system translates to shorter on-scene times, fewer accidents during loading, and increased capacity to respond to multiple calls within a single shift.

Ninety seconds of precise operation can make a chain of events safer for the driver of the disabled vehicle, bystanders, and the operator. The hydraulic platform’s ability to lower to ground level helps accommodate a wide range of vehicle heights and frontal geometries. It also reduces the need for heavy rigging or the use of additional lifting cranes, which are typically found on larger units. This simplicity rewards operators with a more straightforward set of checks and routines, leading to fewer mistakes under pressure and more predictable outcomes as conditions change along a route. The design also minimizes the risk of vehicle rollover or bed instability, which can occur when attempting to lift a poorly secured vehicle in a busy lane. By offering a controlled interface between the ground and the recovery vehicle, light-duty platforms emphasize safety as a fundamental feature rather than an afterthought.

Most light-duty units are calibrated for capacities in the three to six metric ton range, a sweet spot that covers a broad spectrum of passenger cars and small sport utilities. This range aligns with the needs of urban and peri-urban maintenance, roadside assistance fleets, and municipal recovery tasks where speed and reliability trump extreme lifting power. A 3mt to 6mt capability allows operators to handle common city vehicles, plus light vans and small pickups encountered on congested streets. It also supports short-haul transport tasks that demand quick turnover of assets, such as fleet maintenance pickups, service visits to business campuses, or logistical runs within a metropolitan corridor. The relative lightness of these chassis enhances fuel efficiency, reduces tire wear, and lowers maintenance costs compared with heavier heavy-duty models. In a market where fleet total cost of ownership increasingly determines purchasing decisions, this balance between capability and economy is a central selling point for light-duty tow trucks.

Beyond raw lifting capacity, the modern light-duty tow truck is a compact, purpose-built platform designed to integrate with broader service operations. Some configurations emphasize open-body versatility, which makes these trucks ideal for urban rescues, short-haul deliveries, or rapid response missions where weather exposure is acceptable or easily mitigated by tarp or cover systems. Other variants lean toward enclosed van designs, providing weather protection and enhanced security for tools, equipment, and sensitive cargo. The enclosure also contributes to better driver comfort and reduced exposure to road dust, rain, or road spray, which can be important when technicians are transporting essential parts or delicate components. In both cases, the platform bed remains the central mechanism, while the surrounding body styles adapt to the operator’s mission profile.

The reliability of light-duty towing in daily operations hinges on thoughtful integration with the broader fleet and with the local traffic ecosystem. For instance, in emergency rescue operations, light-duty units serve as the fast-response element that clears lanes, stabilizes a scene, and initiates the subsequent steps of recovery. Their small footprint, tight turning radius, and light weight make them particularly suited to congested urban environments where large tow rigs would create gridlock. These vehicles are frequently deployed by roadside assistance programs and municipal services because they can park and operate in spaces where larger apparatus cannot. In this context, their value goes beyond simply moving a vehicle; they help preserve traffic flow, reduce the risk of secondary incidents, and support a quick return to normalcy after a disruption.

The operational versatility of light-duty tow trucks extends into fleet maintenance and small-scale logistics. For fleets that manage a patchwork of company cars, service vans, and transit shuttles, the ability to move, retrieve, or reposition a vehicle with minimal downtime is a strategic asset. Light-duty platforms are well matched to routine maintenance stops, on-site inspections, and even urgent repairs that require a vehicle to be brought to a service bay. The compact size also enables efficient routing, ensuring that tow operators can cover more ground in a single shift. For courier services or spare parts logistics, the combination of a rollback bed and a protected cargo area offers a practical means of safeguarding goods during transit, while still maintaining the speed and agility necessary to meet tight delivery windows. The synergy between recovery capability and transport efficiency becomes a core differentiator for outfits that emphasize reliability and disciplined service standards.

Aesthetics and aerodynamics contribute more to fuel economy than often meets the eye. Modern light-duty tow trucks also reflect refinements in chassis and body design. The aerodynamic cab profile, smooth underbody panels, and careful routing of hydraulic hoses and lines reduce drag, deliver steadier highway performance, and produce measurable fuel savings over long routes. While these refinements may appear small in isolation, they compound over repeated shifts to yield meaningful reductions in operating costs. For businesses with high utilization—where a vehicle covers thousands of miles each month—these improvements translate into a lower operating cost per mile and a more predictable maintenance schedule. In a field where margins are often tight, such efficiency gains matter.

Maintenance philosophy for light-duty tow trucks emphasizes accessibility, modularity, and predictable service intervals. The hydraulic systems benefit from components that are straightforward to diagnose and replace, minimizing downtime when a fault arises on a busy night shift. Regular inspections of the rollback bed, winches, and stabilizing features are common practice in fleets that prize readiness. Operators learn to perform quick checks during vehicle handover, ensuring that the platform remains level, the bed extends and retracts smoothly, and the winch system engages without unusual noise or resistance. In the hands of experienced technicians, this simplicity becomes a strategic advantage: fewer surprises on the road and more confidence in the bed’s performance when it is needed most.

From a procurement perspective, light-duty tow trucks present a compelling case for many fleets that are balancing capital expenditure against ongoing operating costs. The initial investment is often modest relative to heavier recovery rigs, and the lifetime savings accrue from lower fuel consumption, reduced maintenance needs, and long service life when properly cared for. The total cost of ownership can be further softened through warranties, robust after-sales support, and the availability of replacement parts in regional markets. Fleets can tailor configurations to their specific needs without paying for capabilities they will never use. For urban services, a modular approach to equipment and equipment mounting can yield significant return on investment. Operators may choose between open-bed configurations for flexibility or enclosed bodies for weather resilience, with each option aligned to service expectations and risk tolerance.

Within the broader ecosystem of road services, light-duty tow trucks interlock with digital and human processes that shape response quality. Dispatch intelligence, driver training, and safety protocols press the equipment to operate at a high level of reliability. A well-planned fleet keeps these units fueled, serviced, and ready, so that when a call comes in, the operator can respond with precision rather than hesitation. The emphasis on rapid response and safe recovery reinforces a culture of professionalism, where every loading procedure, lane clearance, and transport decision is guided by a shared standard of care. In this environment, the rollback bed is more than a mechanical feature; it is a tool that enables humans to perform more effectively, preserving vehicle integrity, protecting road users, and preserving the timeline required for efficient operations.

As these light-duty platforms continue to evolve, manufacturers and fleets alike are exploring ways to extend their usefulness without compromising their core strengths. For fleets that serve multiple city geometries, the ability to adapt weight distribution, adjust the bed height, and customize shelving or tool storage can transform the vehicle into a small, mobile workshop. Temperature-controlled options, when needed, add another layer of capability for transporting sensitive parts or equipment that must remain within strict climate boundaries. Even with these advanced features, the fundamental operating principle remains unchanged: maximize loading efficiency, minimize on-scene exposure, and deliver dependable transport in a compact platform that respects urban constraints. The result is a class of recovery vehicles that are both practical and resilient, built to handle the everyday realities of city life while remaining ready for the exceptional circumstances that can emerge on any highway or back street.

For readers looking to connect these ideas to real-world practice, consider how a responsive fleet engages with the immediate demands of urban mobility. A single light-duty unit can transform a blocked roadway into a maintainable work zone, setting the stage for coordinated recovery and then a swift return to traffic. This is not just about moving cars; it is about enabling services that keep people moving, reduce the duration of disruptions, and support the reliability of essential transportation networks. When the topic shifts to policy, standards, and training, these vehicles illustrate a practical intersection between engineering, operations, and safety culture. The rollback bed embodies a principle that is easy to overlook in planning meetings: the simplest tool done well often delivers the most reliable performance under pressure.

In summary, light-duty tow trucks deliver a blend of capability and economy that matches the needs of busy urban roadways. They excel at loading small and midsize vehicles with a high degree of safety, offer versatility through flexible body configurations, and support a wide range of service activities from roadside rescue to small-scale logistics. Their design celebrates efficiency without sacrificing reliability, and their role in daily life proves that recovery work can be both technically straightforward and profoundly impactful. As cities continue to grow and traffic patterns become more complex, these compact recovery platforms will remain a foundational element of road safety, fleet readiness, and rapid response. They are the dependable workhorses that keep traffic moving when a vehicle breaks down, a wheel locks up, or a roadside incident demands immediate attention.

For practitioners, researchers, and planners, the takeaway is clear: investing in well-designed light-duty tow trucks yields dividends in speed, safety, and service quality. The best configurations align with the realities of the operating environment, the expectations of customers, and the long-term goals of the fleet. When these elements converge, the result is a resilient, adaptable, and responsible approach to vehicle recovery that respects both the people involved and the infrastructure that keeps communities connected.

Internal link: For organizations prioritizing rapid, coordinated responses across fleets, examining established resilience practices and emergency-readiness frameworks can provide valuable context. See the discussion on fleet readiness here: Fleets Emergency Response.

External resource: A deeper dive into modern light-truck configurations and their standardization within manufacturing practices can be found in industry documentation and manufacturer overviews. External readers may consult generalized technical summaries and official product pages for broader background and benchmark comparisons, such as the information available at the following external source: https://www.sinotruk.com/en/products/light-truck/howo-light-truck-series.html

In the Grip of Recovery: The Power, Precision, and Systems Behind Heavy-Duty Towing Trucks

Heavy-duty towing trucks sit at a crucial intersection of power, precision, and restraint. They are not mere transports that haul a disabled vehicle from one curb to another; they are mobile rescue and recovery platforms designed to endure extreme stress, weathering the imperfections of real-world scenes where safety and speed must coexist. At their core lies a philosophy of rugged dependability: a vehicle engineered to withstand the harsh realities of roadside incidents, industrial shutdowns, and emergency operations while maintaining control under pressure. The vehicles themselves embody a blend of reinforced engineering and adaptable systems, where the chassis, the hydraulics, and the control interfaces are aligned to deliver reliability even when every decision carries weight. In this sense, heavy-duty tow trucks function as highly specialized tools. They are built to respond to scenes that demand more than brute force; they require finesse, situational awareness, and a methodical approach to each maneuver, from the earliest assessment to the final safe placement of a recovered vehicle.

The structural backbone of these machines emphasizes resilience. They are typically anchored on high-strength steel frames that can absorb and distribute extreme loads without compromising the safety of operators or bystanders. This foundation supports a suite of powerful recovery features and robust mechanical linkages that must perform consistently across a wide range of conditions. The design philosophy prioritizes ease of maintenance and long-term durability, recognizing that these vehicles are deployed in municipal fleets, industrial settings, and emergency response teams where downtime can translate into lost hours of capability for a community or a company. Consequently, the utility of the chassis is measured not only by its raw weight-bearing capacity but also by how well it accommodates a spectrum of recovery configurations, including different winch setups, mounting points for stabilization accessories, and mounting provisions for rotator components. The result is a platform that can flex to meet changing operational demands while preserving predictable performance under demanding circumstances.

Integral to the heavy-duty profile is a suite of recovery systems that extend beyond the simple pull of a line. The winch, a central element in any tow unit, is often the most visible symbol of power. Modern heavy-duty models feature winches capable of substantial pulling capacities, with configurations that can range into the high tens of tons. In practical terms, this translates to the ability to extract heavily damaged, immobilized, or playfully stubborn vehicles from mud, ditch crossings, or sloped terrains where a lighter machine would falter. A 16-ton class winch, for example, represents more than a number; it is a ceiling on the amount of resistance that the operator can apply before escalating the recovery to additional tools or crane-assisted methods. The winch capacity is paired with careful drum and rope design, brake systems, and temperature management to ensure sustained performance in real-world conditions. The relationship between power and control is essential here: a high-capacity winch must be matched with operator interfaces and safety interlocks that prevent over-tensioning and protect the line from fatigue and failure. In practice, the operator’s ability to read the scene—assessing surface conditions, vehicle angles, and the interplay of multiple recovery lines—determines whether the winch becomes a swift solution or a risky appraisal of force.

Control over the operation is another defining feature of heavy-duty tow trucks. Operators benefit from a combination of mechanical and hydraulic interfaces that offer intuitive, tactile feedback. A manual transmission system, in particular, is prized for the precision it affords during complex maneuvers. In crowded or hazardous environments, automatic systems can sometimes obscure the subtle chain of reactions required to place a vehicle precisely where it is needed. A manual transmission allows the operator to modulate power delivery with immediate responsiveness, translating to smoother line tension adjustments, better control when negotiating uneven terrain, and safer staging of a recovery. In the best configurations, the control layout is designed around the operator’s workflow: gear shifts that synchronize with the winching action, brake and throttle inputs that remain predictable under load, and integrated diagnostics that surface real-time machine health. This kind of control is crucial when timing the sequence of movements—first securing the vehicle with stabilizers, then applying winch tension, and finally coordinating any rotating action needed to align the vehicle for safe loading and transport.

Among the most visible innovations in heavy-duty recovery is the rotator wrecker body. The rotator enables the operator to rotate and reposition vehicles that are hard to access or precariously positioned. This capability is especially valuable when a vehicle is lodged in a difficult angle or when it must be rotated into a position that permits safe winching and loading. The rotator’s range of motion adds a layer of versatility that reduces the need for multi-step repositioning with multiple vehicles and reduces exposure to hazards for responders. It is a force multiplier in terms of safety and efficiency: the ability to adjust a vehicle’s orientation on the spot minimizes the risk to crew members and facilitates a quicker, more controlled recovery. The rotator is also a reminder that heavy-duty towing is a field where mechanical prowess and spatial reasoning converge; success relies on coordinating multiple axes of movement while continuously monitoring line tensions, vehicle condition, and site geometry. In this sense, rotator-equipped platforms exemplify the blend of power and precision that defines the genre.

Environmental considerations are increasingly woven into the specifications of heavy-duty towing equipment. Emission standards have progressed beyond compliance to shape operational choices and lifecycle planning. Euro 3, a benchmark cited in the present discussion, illustrates how modern heavy-duty tow trucks strive to balance performance with sustainability. Vehicles designed to meet such standards employ more efficient engines, refined combustion processes, and after-treatment systems that reduce the release of pollutants without sacrificing pulling power. The trend toward cleaner operation aligns with wider municipal and corporate goals: reducing the environmental footprint of essential emergency and recovery services while maintaining the reliability that responders rely on. For operators, this intersection of power and responsibility translates into careful considerations during procurement and ongoing maintenance, as well as a commitment to ensuring that recovery crews can operate within regulatory frameworks without compromising mission-critical outcomes.

The recovery toolkit on these trucks goes beyond the winch and rotator. Hydraulic lifts, additional stabilizers, and sometimes mounted cranes broaden the range of tasks that a single unit can handle. In industrial or municipal contexts, a tow truck may encounter scenarios that require lifting, stabilizing, or repositioning a disabled vehicle while negotiating limited space, traffic management, and ground conditions. Each component must be designed to integrate with the others, delivering synchronized action and predictable performance. The broader ecosystem—tools that enable precise alignment, targeted loads, and controlled movement—becomes essential when the objective is to recover a vehicle quickly and safely, even in challenging environments. From the operator’s perspective, the ability to adapt the same chassis to different configurations reduces downtime, extends useful service life, and supports the economics of a fleet that faces a continuous stream of diverse recoveries.

The scope of use for heavy-duty towing trucks encompasses more than roadside rescue. Municipal fleets leverage these vehicles to clear blocked roads after accidents, remove illegally parked or abandoned vehicles, and support rapid response during disasters that disrupt normal traffic. Industrial operations may employ heavy-duty tow trucks to manage logistics and maintenance tasks in yards where heavy equipment moves between work zones. The urban environment, with its concrete canyons and variable surface conditions, presents a unique challenge that these trucks are specifically designed to address. The combination of high-load capacity, robust control interfaces, rotator functionality, and adaptable tooling enables crews to arrive prepared for whatever the scene demands, with a clear plan for stabilizing, extracting, and transporting the target vehicle to a safe location. In many agencies, this is part of a broader philosophy of standardization and readiness—an approach that ensures operators can perform complex tasks with a shared set of procedures, tools, and vocabulary. Within fleets, standardization in heavy-duty rescue operations helps crews synchronize equipment and procedures.

From a maintenance standpoint, the durability of heavy-duty tow trucks rests on disciplined care. The heavy loads, dynamic forces, and varied terrain they encounter require a rigorous maintenance regimen that emphasizes preventive servicing, component wear monitoring, and timely part replacements. The operating cycle for these machines often includes long stretches of highway travel followed by short, intense bursts of activity at recovery sites. This pattern demands parts availability, efficient service turnaround, and well-coordinated logistics for after-sales support. In practice, maintenance needs touch every subsystem: the winch drum and line, the hydraulic circuits, the rotator actuators, and the chassis lubrication network. A well-managed program extends brake life, preserves hydraulics, and helps ensure torque and stability in demanding recoveries. It also supports safer operations by reducing the chance of unexpected failures in the middle of a lift or pull. Fleet operators understand that the total cost of ownership is not simply the sticker price but the sum of reliability, service networks, and the ability to meet uptime commitments during storms, strikes, and other events that demand rapid response.

Procurement decisions for heavy-duty towing equipment reflect another layer: certification, supplier support, and the ability to customize. The market recognizes that agencies and businesses require equipment that aligns with ISO9000 quality management standards, as well as national certifications such as CCC and CE marks, depending on the region. Beyond the certificates, buyers expect after-sales service and warranty coverage that can translate to quick repairs, parts availability, and competent technicians. The emphasis on customization means that buyers and builders collaborate to tailor lifting capacities, winch line configurations, mounting points, and control layouts to local conditions and operational protocols. A vehicle built for one coast might need different weather protection, a different line tension range, or a more robust cooling system to withstand the heat of summer road operations. In this sense, the heavy-duty tow truck becomes not only a tool but a platform for ongoing innovation within public safety and industrial logistics.

The human element remains central. Operators must be trained not merely to run the machine but to read scenes with a disciplined approach to risk and safety. The sequences of steps in a heavy-duty recovery—assessing scene safety, stabilizing the vehicle, deploying winch lines, maintaining tension, coordinating rotator movements, and ensuring the unit is secured for transport—require a blend of technical knowledge and situational judgment. Training programs that emphasize standardized procedures, hands-on practice, and scenario-based drills help crews perform with confidence on every call. This is where the chapter’s focus on capabilities aligns with the broader theme of readiness: the equipment is powerful, but it is the people who harness that power in a way that minimizes risk to themselves and the public.

The narrative of heavy-duty towing trucks, therefore, is not a catalog of components; it is a story of how a single vehicle integrates structural strength, mechanical versatility, and human expertise to recover, stabilize, and move vehicles that would otherwise pose unpredictable hazards. It is a narrative of teamwork between machine, operator, and environment, where every control input must be considered in light of ground conditions, vehicle load, and the ultimate objective of safe, secure transport. In this sense, the heavy-duty tow truck embodies the practical synthesis of engineering ambition and real-world duty: a disciplined tool for an essential service that keeps traffic moving, preserves safety, and supports communities in moments of disruption. The specifications discussed—winch capacity, manual control for precision, rotator capability, and emissions-conscious design—are not isolated figures but parts of a coherent system that speaks to the responsibilities and possibilities of modern recovery work. For practitioners, the takeaway is clear: power without control is dangerous; control without capability is insufficient. The strongest configurations bring both into balance, delivering reliable performance when it matters most and underscoring the idea that the road to recovery is paved not just with muscle but with deliberate engineering and practiced hands. Further technical details can be found at Caterpillar’s tow-truck information page: https://www.cat.com/en/products/vehicles/tow-trucks.html

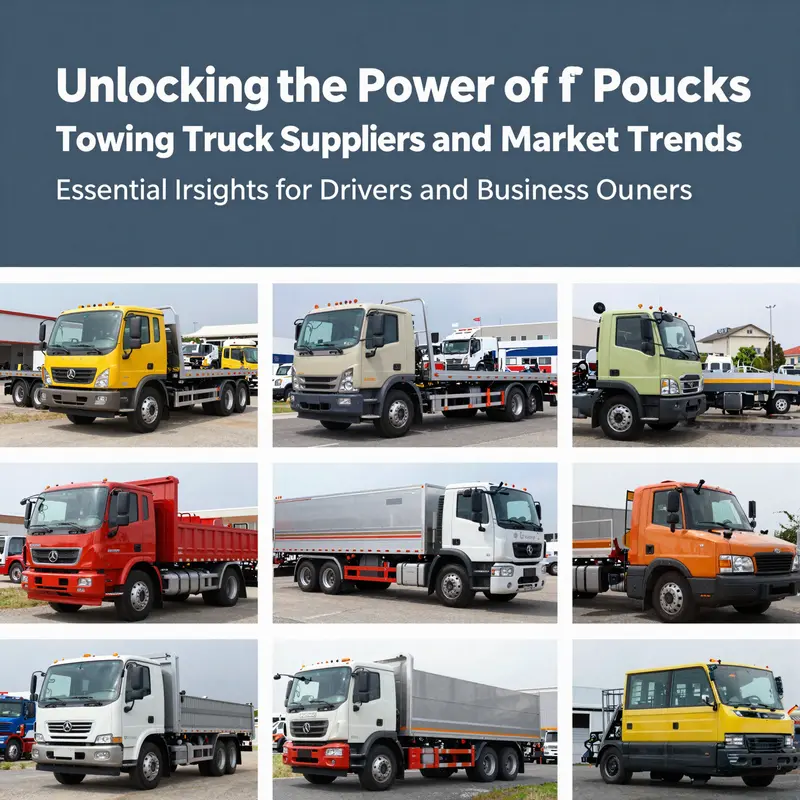

Wheels of Recovery: How Market Dynamics and Chinese Hubs Shape the Tow Truck Industry

Tow trucks sit at the junction of urgency and logistics, a working backbone for road safety and the efficiency of modern transport networks. They are not mere mechanical conveyances; they are mobile recovery platforms, engineering systems on wheels, capable of lifting, winching, and securing vehicles that have failed, collided, or been sidelined by congestion. In many regions, the demand for these specialized vehicles has matured beyond simple road assistance. It now intertwines with urban expansion, supply-chain resilience, and the growing need to maintain critical mobility during incidents that can cascade into far-reaching delays. Across continents, fleets operate in an environment where the speed of response matters as much as the reliability of the equipment. In this context, the market for towing trucks has begun to reflect a more nuanced pattern: demand for versatile configurations, higher payloads, and smarter onboard systems grows in tandem with the expansion of logistics nodes and the emergence of more demanding safety standards. The result is a landscape where manufacturers, suppliers, and operators must align not only on performance but also on a shared vision of standardization, compliance, and sustainable practice. The trajectory is not merely about building heavier machines. It is about integrating recovery capabilities with predictive maintenance, intelligent routing, and a broader ecosystem of services that can sustain uptime in the most challenging environments. In this sense, the chapter that follows considers how global market dynamics, regional manufacturing clusters, and evolving buyer expectations come together to shape the modern tow truck sector. It examines the forces driving growth, the practical advantages of clustered production capabilities, and the ways in which buyers navigate pricing, customization, and post-sale support in a market that has become both competitive and highly specialized. The conversation extends beyond the truck itself to the ways fleets manage readiness, standardize equipment, and prepare for emergencies. For those responsible for keeping fleets on the move, the interplay between supply chain structure and field performance is not an abstract concept; it is a daily condition shaped by the speed at which parts arrive, the quality of after-sales service, and the ability to tailor a vehicle to a particular operating context while maintaining broad regulatory compatibility. In this framing, the tow truck market appears less as a collection of models and more as a system—one that must be capable of adapting to urban corridors, rural recovery tasks, highway incidents, and the evolving requirements of law enforcement, roadside assistance providers, and private towing operators alike. Within that system, the role of manufacturers and regional hubs becomes paramount because the ability to deliver a flexible, regulation-compliant, and affordable platform often hinges on the strength of the local industrial ecosystem. The conversations that unfold in this realm reveal a pattern that is both instructive and reassuring for buyers. They show how proximity to a dense network of suppliers can shorten lead times, streamline customization, and simplify the complex task of ensuring that a vehicle meets an array of international standards. In places where clusters have grown around special-purpose vehicle production, the supply chain benefits from a tightly knit sequence of components: chassis integration, hydraulic systems, control electronics, and the final assembly work that translates a design into a working tow truck. The net effect is a reduction in non-value-adding delays, a clearer path to compliance, and a more predictable schedule that allows fleets to align procurement with maintenance cycles and operational windows. This is particularly evident in regions where the workshop ecosystems are integrated with the broader automotive landscape—where suppliers, engineering teams, and final-assembly plants benefit from comparable manufacturing rhythms, a shared vocabulary around performance metrics, and a collaborative approach to testing and validation. In such locales, clients can expect a higher degree of customization without sacrificing reliability. They can request features that address local regulatory requirements, climate conditions, road geometry, and typical recovery scenarios while still benefiting from the scale economies that come with a well-structured industrial cluster. For fleet operators, this translates into a practical advantage: the ability to tailor a platform to a city’s particular mix of urban, suburban, and rural challenges, to plan for standardization across a multi-vehicle lineup, and to do so with the assurance that spare parts and technical support will be accessible in a reasonable time frame. The value proposition extends beyond procurement into the maintenance phase. When a repair or retrofit is required, the proximity of a cluster that handles everything from hydraulic systems to electronic controls can dramatically shorten downtime. What may once have required cross-border logistics and longer wait times now becomes a matter of ordering a compatible component from nearby suppliers, or scheduling a service visit with technicians who share familiar protocols and diagnostic tools. In the context of a global market that is increasingly sensitive to total cost of ownership, the ability to reduce lead times and ensure long-term availability of parts is as critical as the initial price tag. The pricing landscape itself has become more nuanced as well. Market analyses indicate that the base price of flatbed and rollback tow trucks varies across regions and configurations, with a broad spectrum that reflects capacity, payload, and the degree of customization demanded by buyers. This nuance matters because it affects total cost of ownership over the vehicle’s life cycle: maintenance costs, parts availability, and the expected frequency of updates to meet evolving standards. A key takeaway for buyers is that price should be evaluated in the context of reliability, service networks, and the certainty of regulatory compliance. A lean initial investment can be prudent in markets with robust after-sales support and rapid access to parts, while more complex configurations, requiring higher engineering content, may justify a higher upfront expenditure when they reduce downtime and improve recovery outcomes. Buyers increasingly seek partners who can provide not just a vehicle but a full ecosystem of services: financing options, warranty coverage, spare parts supply, and technical assistance that keeps the fleet in service. The emphasis on after-sales support has grown in response to the operational realities of towing work, where each hour of downtime can translate into lost revenue and customer dissatisfaction. The value proposition of a vendor, then, extends into the service network, the schedule for parts replenishment, and the ability to deliver updates that improve performance, fuel efficiency, or safety features. In this climate, platforms that verify certifications and standards become valuable because they help buyers reduce risk in cross-border procurement. A robust compliance posture reassures operators who must navigate multiple regulatory regimes when operating in different jurisdictions, or that must align with insurance requirements that govern large-tow operations. It is here that the concept of standardization—across vehicle specifications, maintenance practices, and operator training—emerges as a central strategic asset. The idea is not to impose a one-size-fits-all template but to establish a consistent framework that enables fleets to scale, without sacrificing safety or performance. The strategic importance of standardization becomes especially clear when fleets face emergency scenarios. In many cases, the speed and effectiveness of response depend on the operator’s ability to quickly deploy the right equipment, work within established safety protocols, and coordinate with other responders. In this sense, a standardized fleet becomes an interoperable fleet: a set of compatible tools and procedures that work across municipalities, agencies, and contractors. For fleet managers, this translates into the practical imperative to invest in training protocols and to align maintenance schedules with a common diagnostic language. It also means selecting operating procedures that can be shared with law enforcement teams or highway agencies when operations require coordination and safety oversight. The workflow—from dispatch to recovery—depends on trust in the equipment and the people who operate it. Buyers want to be confident that the machines they purchase will perform reliably in the field, that spare parts will be available in the right quantity and time frame, and that technicians can diagnose issues using standardized diagnostic tools. The market responds to this expectation by promoting ecosystems where manufacturers collaborate with service networks and where parts suppliers maintain local stockpiles, reducing the risk of long downtimes. In these ecosystems, the incentives align toward long-term partnerships rather than transactional, one-off sales. It is also worth noting how the industry is starting to respond to broader sustainability concerns. Electric and hybrid powertrains, while still emerging in heavy recovery roles, signal a shift toward lower emissions and improved efficiency. The uptake of such technologies will hinge on a combination of performance parity, reliability, and the availability of charging and service infrastructure in critical recovery hubs. The transition will be gradual, with traditional hydraulic and mechanical systems still dominating the market for years to come. Nevertheless, the seeds of change are visible, and forward-looking operators already weigh the potential total cost of ownership benefits against the upfront capital required for electric or hybrid configurations. The interplay of these factors—clustered production, competitive pricing, customization, after-sales strength, standardization, and the gradual adoption of greener technologies—frames a market that is robust, dynamic, and highly responsive to the evolving needs of logistics networks and emergency response systems. In that sense, the global tow truck market is less about a single product and more about a living architecture that supports mobility under pressure. It is a system that relies on the reliability of its supply chains as much as on the reliability of its machines, and it is sustained by a network of regional strengths that translate into practical benefits for operators who must meet tight schedules, satisfy regulatory demands, and respond decisively when a vehicle needs to be moved from the scene and back onto the road. For readers seeking deeper insight into how fleet standardization and emergency readiness shape decision-making in this sector, a closer look at specialized resources can provide valuable context and tested practices. fleet standardization and emergency readiness links offer perspectives on aligning equipment with operational needs, training, and the kind of coordinated planning that reduces risk during critical incidents. As markets continue to evolve, buyers will increasingly demand transparency around certifications and a demonstrated capability to support maintenance across regional boundaries, a trend that aligns with the broader push toward standardized, interoperable, and reliable recovery solutions. The external evidence for this trajectory remains accessible through industry analyses that project steady growth and emphasize the strategic importance of supplier ecosystems, cross-border compliance, and the ongoing exploration of electric and hybrid recovery options. For those who want to explore the broader landscape of market dynamics and future projections, a reputable external resource provides a detailed forecast of the tow truck body market, including regional insights and drivers shaping the next phase of growth. https://www.marketsandmarkets.com/Market-Reports/tow-truck-body-market-4789.html

Final thoughts

As we conclude our exploration of towing trucks, it’s clear that these vehicles are integral to vehicle management and roadside assistance across various sectors. From light-duty trucks best suited for urban environments to robust heavy-duty models designed for more demanding recovery scenarios, the breadth of options allows for tailored solutions to meet specific needs. Furthermore, knowing reputable suppliers and market trends empowers car owners, businesses, and property managers to make informed decisions that enhance operational efficiency. Investing in the right towing truck not only aids in effective vehicle recovery but also contributes significantly to the safety and convenience of our roads.